The 7018 welding rod is a low-hydrogen iron powder coated electrode designed for critical welds where high strength and crack resistance are paramount. It delivers excellent all-position welding performance with smooth bead appearance, minimal spatter, and superior mechanical properties.

Widely used in structural steel fabrication, pipeline welding, pressure vessel manufacturing, and bridge construction, E7018 rods produce welds with outstanding toughness and ductility. Its low-hydrogen coating reduces the risk of weld cracking, making it the preferred electrode for critical applications where weld integrity matters.

Key Features

-

Low Hydrogen Coating: Minimizes hydrogen-induced cracking and improves weld quality

-

All-Position Welding: Certified for flat, horizontal, vertical (up/down), and overhead positions

-

Smooth, Slag-Free Finish: Produces a neat, easily removable slag covering smooth weld beads

-

High Tensile Strength: Meets or exceeds 70,000 psi tensile strength requirements

-

Good Impact Toughness: Suitable for low-temperature applications and structural welding

-

Iron Powder Core: Enhances deposition rate and weld bead build-up

-

Operates on AC and DC: Versatile polarity use for different welding machines

7018 welding rods Typical Applications

-

Structural steel frameworks and bridges

-

Pressure vessels and boilers

-

Pipeline fabrication and repair

-

Shipbuilding and heavy equipment manufacturing

-

General fabrication requiring crack-resistant welds

Specifications

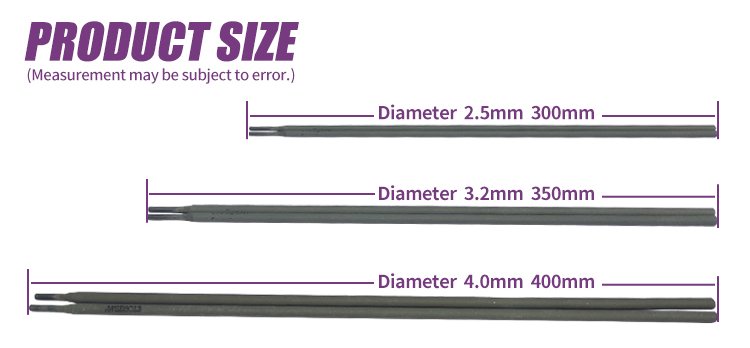

| Diameter (mm) | Length (mm) | Recommended Welding Current | Typical Use |

|---|---|---|---|

| 2.5 (3/32″) | 350 | 60 – 100 A | Thin sections, general fab |

| 3.2 (1/8″) | 350 | 90 – 140 A | Medium thickness welds |

| 4.0 (5/32″) | 350 | 120 – 180 A | Thick plates and heavy welds |

| 5.0 (3/16″) | 350 | 150 – 210 A | Heavy-duty structural welds |

Chemical Composition (Typical Weld Metal %)

| Element | C | Mn | Si | S | P | Ni | Mo | Cu |

|---|---|---|---|---|---|---|---|---|

| Value | 0.08 | 1.0 | 0.35 | 0.010 | 0.010 | 0.40 | 0.25 | 0.30 |

Mechanical Properties (Typical Weld Metal)

7018 welding rods Welding Performance

-

Arc Characteristics: Smooth and stable arc with low spatter, easy to strike

-

Penetration: Moderate penetration suited for structural and pipeline welding

-

Slag: Thin, easy to chip slag for clean bead profile

-

Polarity: Compatible with AC and DC+ or DC- polarity for versatile use

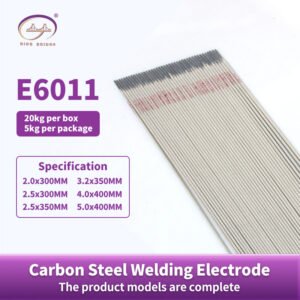

Packaging & Supply

-

Standard packaging: 5kg, 10kg, 20kg boxes

-

OEM/ODM packaging options available

-

Flexible MOQ for sample and bulk orders

-

Fast production with reliable global shipping

Why Choose Our E7018 Welding Rod?

-

Manufactured with strict quality control and premium raw materials

-

Fully compliant with AWS A5.1 / E7018 standards

-

Competitive factory-direct pricing and customization

-

Trusted by clients in Africa, South America, and Southeast Asia

-

Technical support for optimizing welding procedures and parameters

Ready to Order?

Contact our sales team now to get quotations, sample requests, or technical assistance. Ensure the success and reliability of your critical weld projects with our premium E7018 welding rods.

Reviews

There are no reviews yet.