The E6010 (Rutile) welding rod combines the deep penetration strength of traditional cellulose electrodes with the smoother arc characteristics of rutile coatings. This hybrid design delivers a forceful, spray-type arc with enhanced arc stability and less spatter, producing clean, sound welds in all positions.

Engineered for pipeline, structural steel, and repair welding, the rutile flux coating improves slag removal and bead appearance, making it easier to handle in vertical and overhead positions. Its ability to weld on mildly contaminated surfaces—such as rusty or painted metals—makes it highly versatile in field applications and heavy industrial fabrication.

Optimized for DC electrode positive (DCEP) power sources, this rod supports fast freeze slag action and strong root penetration. The rutile-enhanced flux also reduces operator fatigue by smoothing the welding arc, providing a more user-friendly welding experience without sacrificing the toughness and reliability required for critical welds.

Key Features

-

Deep Penetration: Retains the powerful penetration capability of standard E6010 rods

-

Rutile Coating: Smoother, stable arc with less spatter and better bead appearance

-

All-Position Welding: Certified for flat, horizontal, vertical (up/down), and overhead welding

-

Fast Freeze Slag: Thin, easily removable slag for clean welds and minimal post-weld cleanup

-

Contamination Tolerance: Effective on rusty, mill-scale, and painted surfaces

-

Easy Arc Strike: Smooth striking and consistent arc for improved operator control

Typical Applications

-

Pipeline and pressure vessel welding root passes

-

Structural steel fabrication and bridge construction

-

Shipbuilding and marine repair welds

-

Heavy machinery and equipment maintenance

-

Field welding requiring versatility in position and surface condition

-

Multi-pass welds needing strong root integrity

Specifications

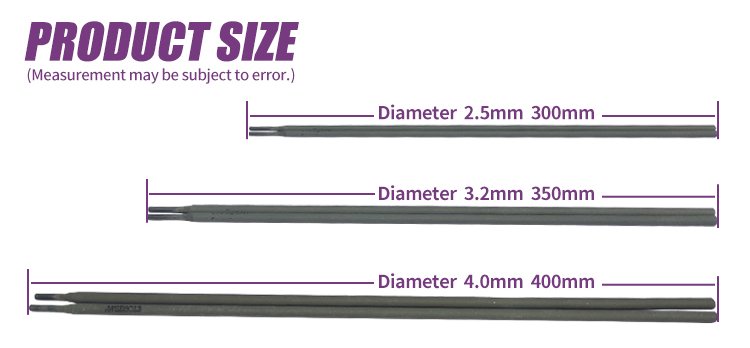

| Diameter (mm) | Length (mm) | Recommended Current (DC+) | Typical Use |

|---|---|---|---|

| 2.4 (3/32″) | 350 | 40 – 80 A | Thin sections, root pass |

| 3.2 (1/8″) | 350 | 75 – 125 A | General fabrication |

| 4.0 (5/32″) | 350 | 110 – 170 A | Thick sections, heavy fab |

| 4.8 (3/16″) | 350 | 140 – 215 A | Pipeline and structural |

Chemical Composition (Typical Weld Metal %)

| Element | C | Mn | Si | S | P |

|---|---|---|---|---|---|

| Value | 0.08 | 0.50 | 0.20 | 0.015 | 0.012 |

Mechanical Properties (Typical Weld Metal)

| Property | Value |

|---|---|

| Tensile Strength | 480 MPa (69,600 psi) |

| Yield Strength | 390 MPa (56,550 psi) |

| Elongation | 26% |

| Impact Toughness | 90 J @ -20°C |

Welding Performance

-

Arc Characteristics: Smooth and stable arc with reduced spatter, easy to control even in out-of-position welding

-

Penetration: Deep and forceful penetration comparable to standard E6010, ensuring strong root welds

-

Slag: Fast-freezing, thin slag that peels easily, maintaining bead cleanliness and reducing cleanup time

-

Polarity: Must be used with DC electrode positive (DCEP) to achieve optimal penetration and arc stability

Packaging & Supply

-

Packaged in 5kg, 10kg, 20kg boxes for convenience

-

OEM packaging and branding available to suit your business needs

-

Flexible minimum order quantities for small or bulk orders

-

Fast lead times and global logistics support

Why Choose Our E6010 (Rutile) Welding Rod?

-

Manufactured under stringent quality controls for consistent performance

-

Adheres to AWS A5.1 standards for high-quality electrode specifications

-

Competitive pricing with customizable packaging and labeling options

-

Experienced supplier exporting to Africa, South America, and other key markets

-

Dedicated technical support for welding process optimization

Ready to Order?

Empower your projects with our premium E6010 (Rutile) welding rods. Contact our sales team now to get your quotes, samples, and expert guidance tailored to your applications.

Reviews

There are no reviews yet.