The E6010 welding rod is a cellulose sodium-coated electrode designed for deep penetration and a forceful, spray-type arc. It is an industry benchmark for pipeline welding, structural steel fabrication, and repair in challenging field conditions. Its fast-freezing slag and exceptional arc stability allow clean, sound welds even on dirty, rusty, or painted surfaces.

With its ability to weld in all positions — flat, horizontal, vertical (up and down), and overhead — the E6010 rod is essential for root passes on pipe and thick steel plates. Its high cellulose flux tolerates mill scale and contamination, making it ideal for construction, shipbuilding, oil & gas pipeline welding, and heavy equipment maintenance.

The rod runs on DC electrode positive (DCEP) power, providing a concentrated arc and high-quality weld deposits with a high deposition rate thanks to iron powder in the flux. This makes welding faster and more efficient for large-scale production or repair.

Key Features

-

Deep Penetration: Ensures strong root fusion on pipe and thick sections

-

All-Position Welding: Flat, horizontal, vertical (up/down), overhead capability

-

Fast Freeze Slag: Thin, easily removed slag for smooth bead finish

-

High Cellulose Flux: Tolerates rust, mill scale, paint, and oil

-

Stable Arc & Easy Strike: Smooth striking on DC+ with consistent performance

-

High Deposition Efficiency: Iron powder-enhanced flux for increased weld metal output

Typical Applications

-

Oil and gas pipeline root and fill passes

-

Structural steel and bridge fabrication

-

Shipbuilding and marine repair

-

Pressure vessels and storage tanks

-

Equipment and machinery maintenance in harsh environments

-

Multi-pass welding projects requiring sound penetration

Specifications

| Diameter (mm) | Length (mm) | Recommended Current (DC+) | Typical Use |

|---|---|---|---|

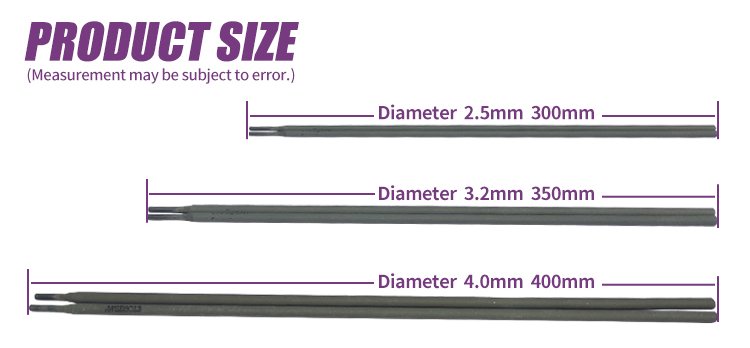

| 2.4 (3/32″) | 350 | 40 – 80 A | Thin sections, root pass |

| 3.2 (1/8″) | 350 | 75 – 125 A | Medium sections, general |

| 4.0 (5/32″) | 350 | 110 – 170 A | Thick plates, structural |

| 4.8 (3/16″) | 350 | 140 – 215 A | Heavy-duty, pipeline weld |

Chemical Composition (Typical Weld Metal %)

| Element | C | Mn | Si | S | P |

|---|---|---|---|---|---|

| Value | 0.09 | 0.55 | 0.18 | 0.013 | 0.010 |

Mechanical Properties (Typical Weld Metal)

| Property | Value |

|---|---|

| Tensile Strength | 500 MPa (72,500 psi) |

| Yield Strength | 405 MPa (58,800 psi) |

| Elongation | 28% |

| Impact Toughness | 96 J @ -30°C |

Welding Performance

-

Arc Characteristics: Spray-type, forceful arc with easy strike on DC+ polarity

-

Penetration: Among the deepest for stick electrodes, excellent for root and heavy welds

-

Slag: Thin, friable, fast-freezing for clean bead profiles and easy slag removal

-

Polarity: Must be run on DC electrode positive (DCEP) for best results; AC or DC- will reduce performance

Packaging & Supply

-

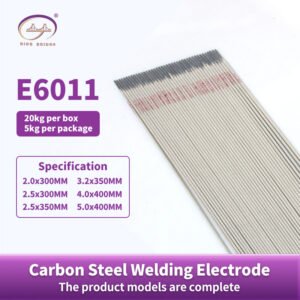

Standard packaging in 5kg, 10kg, 20kg boxes

-

OEM packaging and custom labeling available

-

Flexible minimum order quantities for trials or bulk

-

Fast production lead times and reliable global shipping

Why Choose Our E6010 Welding Rod?

-

Factory-direct supplier with strict quality control

-

Consistent performance meeting AWS A5.1 standards

-

Competitive pricing with OEM/ODM customization options

-

Experienced exporter to Africa, South America, and other global markets

-

Expert technical support to optimize welding parameters and results

Ready to Order?

Let’s power your fabrication and repair projects with our reliable E6010 welding rods. Contact our sales team today for quotations, sample requests, and technical assistance.

-1-300x300.jpg)

Reviews

There are no reviews yet.